Apparel & Footwear: Standard Allowed Minutes (SAM)

Hector Ritondale examines how the Apparel & Footwear Solution for SAP Business One makes the most of SAM for optimum levels of efficiency.

In an industry where speed to market is of the utmost importance but where sub-standard products simply won’t do, optimizing operations via cost and efficiency savings is what all fashion businesses are striving for. When it comes to the creation of accurate costings, production timescales and effective capacity planning, one of the key factors to consider is the Standard Allowed Minutes or SAM of a particular garment.

What is SAM?

The concept of Standard Allowed Minutes is used to measure the work content of a garment, so the time taken for an operator or machine to complete a specific task when working at 100% efficiency. It’s impossible to estimate SAM without seeing and/or analyzing a garment, as a number of different factors need to be taken into account, such as length of seams, fabric types, stitching accuracy needed, and dewing techniques to be used, to name but a few.

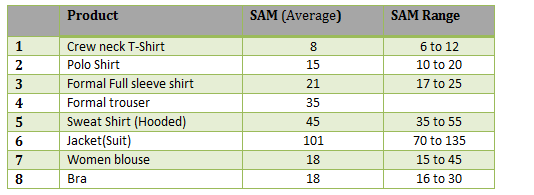

Obviously it’s not possible or practical to do this for every individual garment that’s designed, but below are some SAM estimations for basic products, alongside SAM ranges to take into account some of the aforementioned variables.

Using these estimated SAM values and ranges can inform the capacity planning of the factory, calculating machinery requirements, line capacity and helping to estimate the cut and make costs of the garment in question.

SAM and SAP Business One

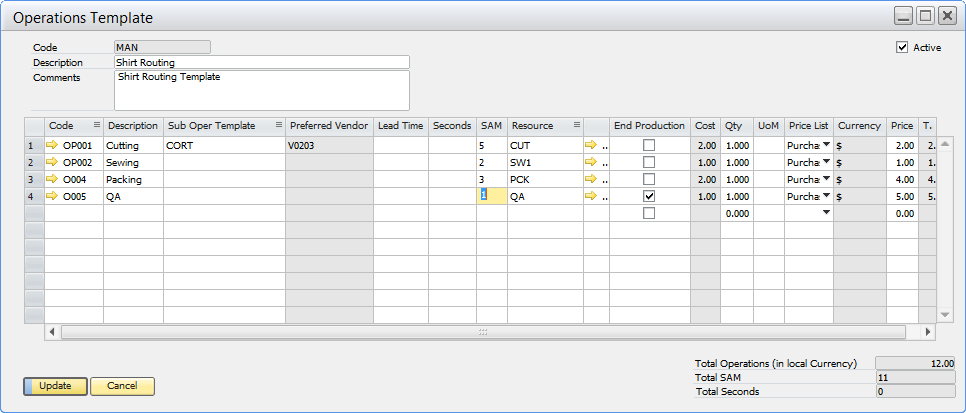

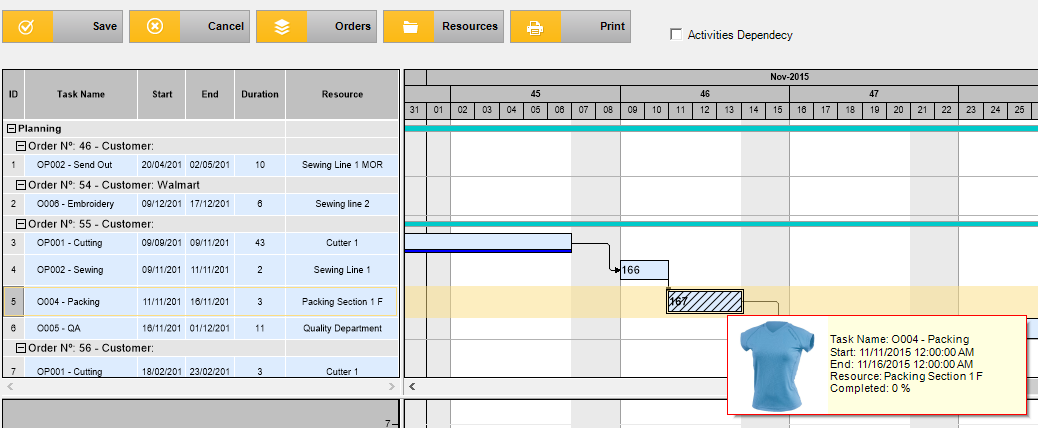

When it comes to optimizing manufacturing operations using the Apparel & Footwear Solution for SAP Business One, SAM values play a vital role. Take the example below, which shows the routing template for a standard shirt, where the total SAM is 11 minutes. Within the system, the user can adjust the SAM for each operation, and each operation can be linked to a default resource to be used in manufacturing planning. Based on resource capacity and efficiency, the SAP Business One planning engine will then program start and end dates for manufacture, as well as proposing the best resources for the operation. In short, the system makes a potentially complex part of the planning process, much more straightforward, saving time and resulting in much more efficient operations.

For more information on how Argentis can help your fashion business optimize operations, contact us.